Stainless Steel 304L Channel is a well-known structural item which is designed using low-carbon 304 stainless steel. Channels made of 304L steel with its excellent anti-corrosion properties, better weld ability, and high strength are very frequently found in the structural frameworks, equipment supports, and architectural installations. Being a reduced carbon form of 304 it can be easily welded with good mechanical properties.

Inquire Now

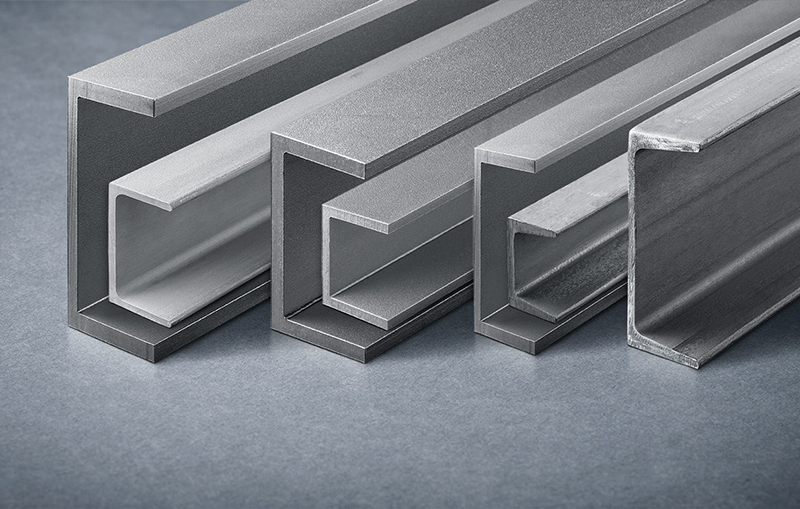

Stainless Steel 304L Channel channel is a structural profile that is a steel with AISI 304L stainless steel, it is an austenitic alloy with industrial designation S30403. The 304L has an L in it meaning low carbon, the maximum allowed is 0.03% with this it reduces the amount of carbide precipitation that occurs when welding.

It contains 18-20 percent chromium, 8-12 percent nickel in its composition, which is great in oxidation resistance and corrosion resistance. It is designed in a shape of a channel, typically "C an improvement shaped, so it can be used in load bearing, framing as well as bracing.

| Property | Value | Unit |

|---|---|---|

| Chemical composition | Cr: 18-20, Ni: 8-12, C: ≤ 0.03, Mn: ≤ 2.0, Si: ≤ 1.0, P: ≤ 0.045, S: ≤ 0.03 | % |

| Tensile Strength | 485 | MPa |

| Yield Strength | 170 | MPa |

| Elongation | 40 | % |

| Hardness | 170-190 | HRB |

| Density | 7.9 | g/cm³ |

The following are some of the benefits of using Stainless Steel 304L Channel because of the following properties:

There are a number of advantages related to the use of Stainless Steel 304L Channel approaching either performance or cost-related:

The stainless steel stainless Steel 304L channel provides a unique combination of ease of welding, corrosion resistant and structural strength. Its composition is quite low in terms of C and this makes it aptly suited in high-heat and welded applications but also the strength of its mechanical properties make it suitable in heavy structural application demands.