Stainless Steel 310 Channel is moulded and high alloyed and heat resistant structural outline profile applied in high-temperature environments and harmful atmosphere. SS 310 Channels are durable, stable and sturdy built with long duration properties and can be used in several products of industries such as construction of furnaces, heat exchangers, petrochemical processing lines etc. These channels perform better than typical stainless steels grades in high-stress conditions due to their highly corrosion-resistant oxidation capabilities and great resistance to deformity at elevated temperatures.

Inquire Now

The Structural steel profile Stainless Steel 310 channel belongs to an AISI 310 stainless steel material and is under the code UNS S31000. It is also austenitic stainless steel made of 25 percent chromium and 20 percent nickel; it is, therefore, one of the most stainless steels that can resist heat and oxidation.

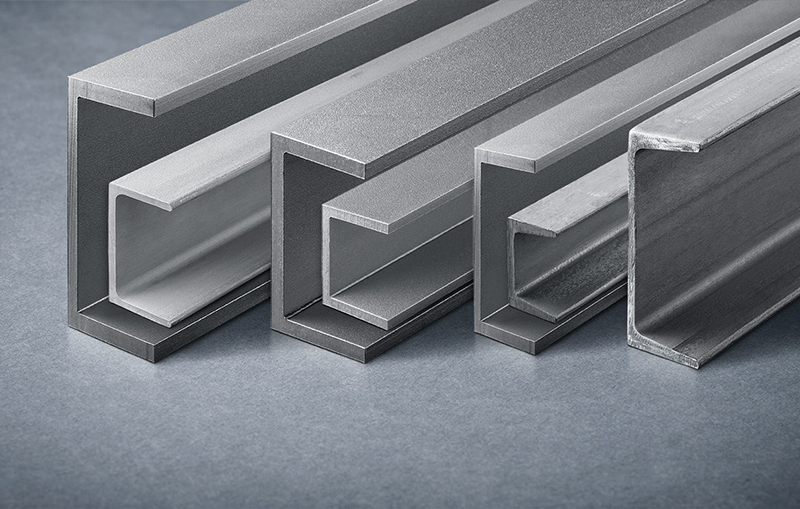

It has a low carbon content to ease the chances of carbide precipitation during welding and has high chromium and nickel alloy composition to strengthen the oxidation, suffixation as well as scaling resistance even at temperatures above 1100o c (2012o F). It has a better load distribution and rigidity due to channel design usually in a C or U shape, which is appropriate to supportive structures where they have to take some load.

Stainless steel 310 Channel can also be distinguished by its high surviving capability in harsh conditions. The important characteristics are:

The Stainless Steel 310 Channels are designed in order to be applied in the areas which need a great amount of heat resistance, strength, and corrosion insurance. The industries and applications are:

When picking the Stainless Steel 310 Channel one will benefit in a number of distinctive ways:

Stainless Steel 310 Channel is the profile of choice in high-stress and high temperature applications. It is so strong, resistant to oxidation, and structurally reliable that it cannot be missing in any petrochemical, power generation, and thermal processing industry. All environments are subject to heavy-use some furnace enclosures might be constructed and others want to support the industrial systems; SS 310 Channel has the potential to perform and last under your workload.