Stainless Steel 316 is a multi-purpose structural element with which unusual power of resistance to corrosion and strength is attributed. It is mainly composed of chromium, nickel, and molybdenum, and it provides better stability in the case of exposure to the harsh environments such as marine and chemical environments. This makes it the best product in those industry that demand durable and reliable materials. This article is going to discuss the main characteristics of Stainless Steel 316 Channel and the main usage of the channel and benefits of its using, so you will be well-informed about its possibilities.

Inquire Now

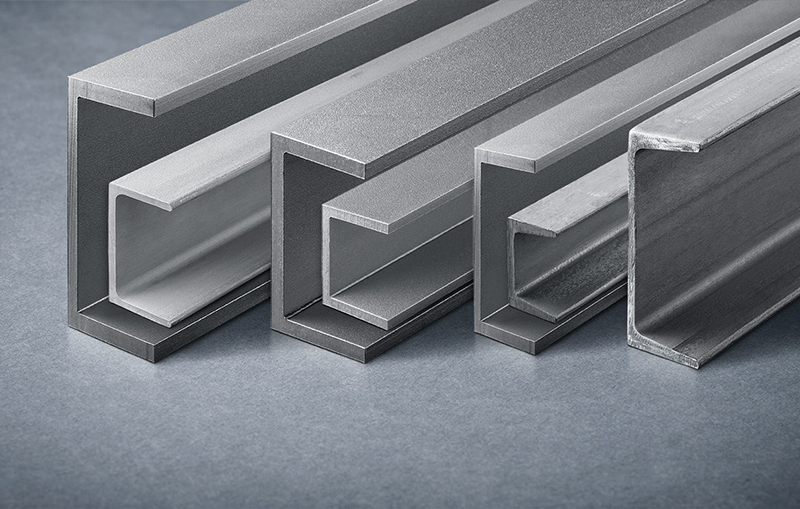

Stainless Steel 316 Channel is the name of structural steel cross section that has a shape like the letter C; it has many applications including construction and manufacturing. The name 316 denotes the composition of alloys that include a percentage of 16-18 percent chromium, 10-14 percent nickel, and 2-3 percent molybdenum. This is in addition to increasing its corrosion and its oxidation resistance especially in environments rich in chlorides. The shape of the channel makes it strong and also supports it in multiple structural terms.

The channel shape made of stainless steel 316 can be applied in many industries because of its strong components:

Stainless Steel 316 Channel is an ideal and strong material that fits most of the applications, especially in the area at risk of corrosive factors. It is reliable in producing superior structures with good corrosion resistance, strength, and weldability qualities hence its good usage in most industries like marine, chemical processing, construction and food processing. The choices of materials to be used in the constructions components should be made based on strength and the other benefits Stainless Steel 316 channel can bring to the project, and the service life of a construction project can be maximized.