A stainless steel 316L Channel is known to be an exceptionally durable and highly corrosive structural profile, which is to be used in a challenging environment requiring high levels of chemical resistance and sustainability. The 316L variant of stainless steel is low-carbon stainless steel especially applicable in welded assemblies since they do not pose the risk of intergranular corrosion, and they maintain the integrity of their structure with time. Whether in construction of buildings along the coast, or support lofts in chemical and pharmaceutical industries, the Stainless Steel 316L Channels is given priority in a number of challenging industries.

Inquire Now

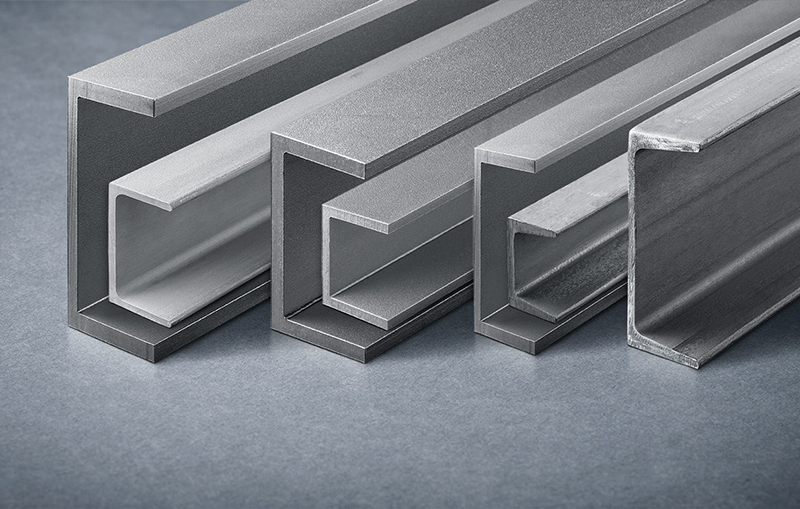

Stainless Steel 316L Channel is a structural shape composed of a C-shaped or a U-shaped part, manufactured with 316L stainless steel, which can be regarded as an austenitic alloy known as a designation UNS S31603. The "L" is used to mean low carbon, a factor which adds to the weld ability and resistance to sensitization (intergranular corrosion) through the welding process or exposure to high temperatures. Molybdenum addition increases chloride resistance and resistance to an acidic media thus suitable in both marine environments and chemical processing purposes.

Stainless Steel 316L Channels have a characteristic combination of strength, corrosion resistance and ease of fabrication, among others:

Being a much better choice in terms of corrosion resistance as well as mechanical properties, Stainless Steel 316L Channel is commonly implemented in various industries:

Stainless Steel 316L Channels are dealt with a number of key advantages as compared with other substances:

Stainless Steel 316L Channel is a structural material of the highest grade that can be used in an environment where its strength and corrosion resistance are essential. And that is why, with its magnificent weld ability, amazing durability and low maintenance figures, 316L Channels are relied upon both in the marine industries, chemical industry and construction industries. Whether you design applications that endure tough environmental conditions, or you simply want a resistant and durable solutions Stainless Steel 316L Channel will be the best solutions.