Stainless Steel 321 Channel is a profile of austenitic stainless steel structure in which high-temperature strength, oxidation resistance, as well as stabilized composition is much popular. The 321 stainless steel is very effective in resisting intergranular corrosion and sensitisation of welding or in long term heating conditions, and therefore is the perfect steel to use in structural applications in areas of heat.

Inquire Now

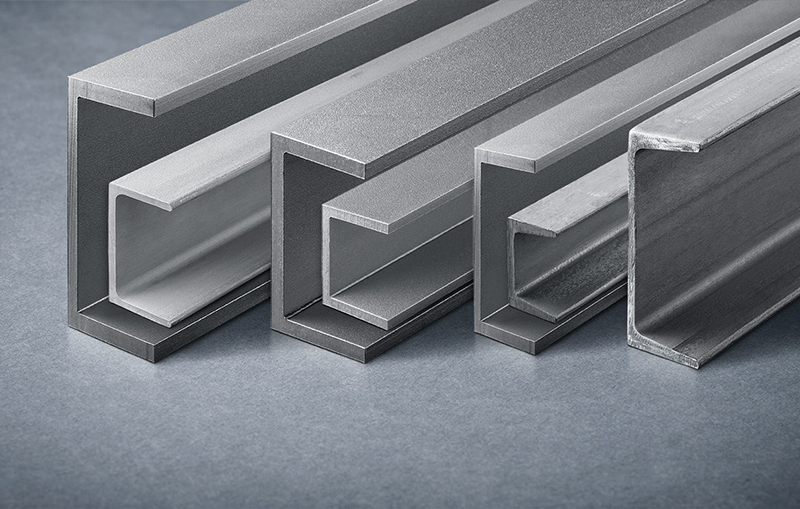

Stainless Steel 321 Channel is a structural steel piece in the form of C or U, which is manufactured of stainless steel 321 (UNS S32100). It is a titanium-stabilized modification of Type 304 stainless steel and has even better resistance to intergranular corrosion of the same metal after it has been affected by hard-hitting to the chromium carbide precipitation (400 to 850o C).

Its major composition is chromium (17-19%), nickel (9-12%), and titanium (=5x of carbon content). The titanium binds with carbon and so no carbide formation occurs on welding or when subjected to heat. Consequently, Stainless Steel 321 Channel is preferable in the formulation of pressure vessels, exhaust pipes, and places that need constant heat resistance and mechanical strength.

| Property | Value | Unit |

|---|---|---|

| Chemical composition | Cr: 17-19, Ni: 9-12, Ti: ≥5x C, C: ≤0.08, Mn: ≤2.0, Si: ≤1.0, P: ≤0.045, S: ≤0.03 | % |

| Tensile Strength | 515 | MPa |

| Yield Strength | 205 | MPa |

| Elongation | 40 | % |

| Hardness | 217 | HRB |

| Density | 7.92 | g/cm³ |

The following is why when it comes to high performance environments Stainless Steel 321 Channels can be considered a material of choice:

The material Stainless Steel 321 Channel is a high performance product designed to address structural components that require weld ability, thermal stability and resistance to corrosion. The titanium-stabilized content brings it with a unique resistance to corrosion intergranularly- this is highly useful in applications that are heat-intensive and also in welded applications.