Structural product Stainless Steel 410 Channel is a high-strength, heat-treatable martensitic stainless steel product that has the benefits of good wear resistance and high hardness and moderate corrosion resistance. As well as being constructed such that it has high mechanical performance attributed to it, 410 stainless channels frequently find use in construction work, industrial fabrication and assembly works.

Inquire Now

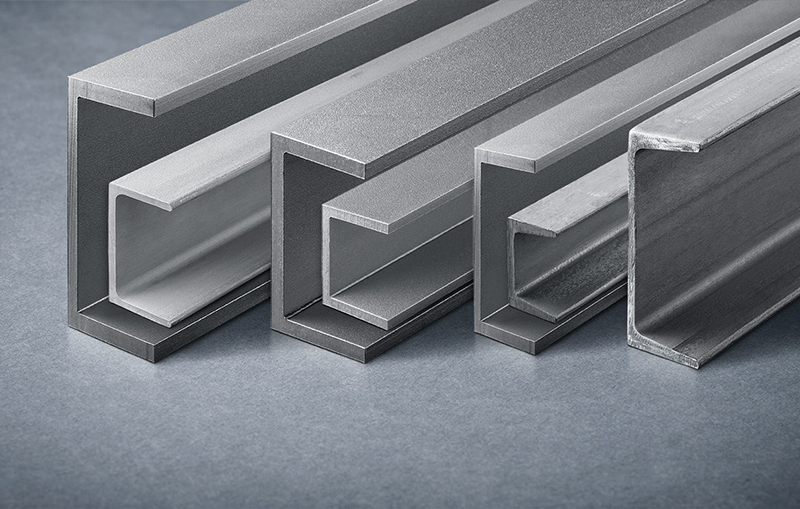

A Stainless Steel 410 Channel is c or u shaped structural profile manufactured in Grade stainless steel 410 also known as UNS S41000. This martensitic stainless steel contains a slightly increased weight of chromium (11.5-13.5 percent), a relative large weight of carbon which facilitates it to receive heat-treatment to achieve strength and hardness.

SS 410 is magnetic and unlike the austenitic grades 304 or 316 it can be hardened by means of heat treatment. It is therefore most appropriate in situations where wear resistance is in conjunction with supremacy of mechanisms is more paramount than maximum capacity as far as corrosion protection goes.

| Property | Value | Unit |

|---|---|---|

| Chemical composition | Cr: 17-19, Ni: 9-12, Ti: ≥5x C, C: ≤ 0.08, Mn: ≤ 2.0, Si: ≤ 1.0, P: ≤ 0.045, S: ≤ 0.03 | % |

| Tensile Strength | 515 | MPa |

| Yield Strength | 205 | MPa |

| Elongation | 40 | % |

| Hardness | 217 | HRB |

| Density | 7.92 | g/cm³ |

Stainless Steel 410 Channel is an excellent performance, cost-effective product fit in case of applications requiring mechanical strength, heat resistance, and abrasion protection. It is not as corrosion resistant as other grades of stainless steel but highly hard enable, formable and durable making it a perfect match in the industrial, automotive and structural fields.